One of the major tire manufacturer in the world, for a new plant in India, chose RODOLFO COMERIO for the manufacturing of an innovative calendering line of 1,900 mm width, able to produce rubberized textile cord and innerliner and that can also be prearranged for the future production of rubberized steel cord, thus maximizing profits and optimizing the return on invested capital.

This “super combined” calendering line will be manufactured in RODOLFO COMERIO facilities in Solbiate Olona, together with the several New-Generation calendering lines equipped with the most recent technologies invented and patented by the Italian manufacturer, ordered by global leader tire manufacturers.

Thanks to the New-Generation calenders provided with the RC SF-FreeSystem patented system of friction-free roll shifting, the tire manufacturers will be able to grant to their customers increasingly performing tires made of calendered material having the following characteristics and advantages:

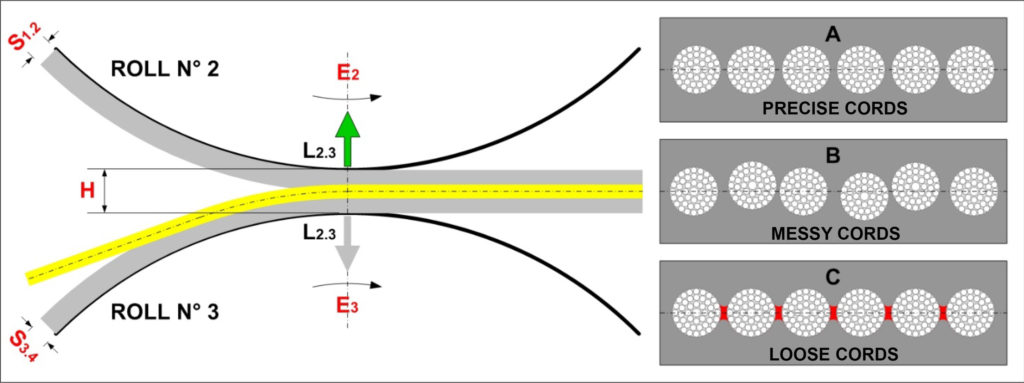

– Improvement of the rubber penetration into the textile or steel cord

– Improvement of the thickness accuracy

– Improvement of the cords distribution end-count per inch (EPI or EPD)

– Possibility of reducing the thickness

– Improvement of the tires rolling performance

– Improvement of the tires resistance performance

– Improvement of the tires stability

– Consequent contribution to vehicle fuel saving

– Raw material saving

– Reduction of scraps

– Consequent cost saving

Moreover, the new technologies and the new systems adopted for the pre- and post-calender sections significantly increase productivity and guarantee high levels of safety for operators, whose manual interventions are considerably reduced thanks to highly automated production process solutions and consist of simply supervising the operations performed automatically by the new generation machines designed by RODOLFO COMERIO.

The “super-combined” calendering line marked RODOLFO COMERIO and destined for the Indian customer will be able to exceed the daily productivity of 370 tons and will be used to produce material for all types of tires, from giants for agriculture to tires for cars and also for those for 2 and 3-wheel vehicles.

RODOLFO COMERIO, thanks to an enormous use of resources, is bringing calendering technology – which in last few years had never known major developments – to levels that until recently were considered unattainable, with the aim of giving an innovative impulse to help its customers improve production yields but also of contributing to improve the performances of the finished product.

The company is also introducing new assistance plans to ensure even faster installations and start-up of plants to guarantee its customers a faster return on investment.

In RODOLFO COMERIO facilities, all the lines are always completely assembled, the tests and dry tests are performed for the solutions customized for the specific customer and, with the aid of 3D simulations, the installation and start-up phases in the customer’s building are simplified. For example, nowadays RODOLFO COMERIO is able to perform a mechanical installation of an entire line for the steel cord rubberizing within a period of time of approximately 2/3 weeks.

With the “RC TURN-KEYinstallation” pack, the Italian manufacturer supplies completely installed and commissioned calendering lines.

The experience gained over one hundred and fifty years of activity and an avant-garde Technical Department allow to offer customers this TURN-KEY pack, which is particularly suited to speed up the process and guarantee customers the maximum experience of the manufacturer.

The Customer thus has the advantage of having a single point of contact, limited responsibility to RODOLFO COMERIO, immediately knowing the final price of the whole plant and its installation and start-up, with no surprises and no need of overall cost containment.

RODOLFO COMERIO is the only interlocutor that deals with everything, more specifically:

• Perform technical inspection

• Study and identify the best solution for installation

• Prepare the necessary documentation

• Appoint the Works Management

• Appoint the Safety Coordinator

• Appoint a project manager

• Draw up a detailed installation program

• Make available any means needed for moving the machines

• Perform electrical wiring

• Perform hydraulic and thermo-hydraulic piping

• Assemble and test the system

• Start up and commission the system

• Perform the training of the customer’s staff through the “RC TRAINING” complete pack:

o RC TRAINING MAINTANANCEService

o RC TRAINING OPERATIONService

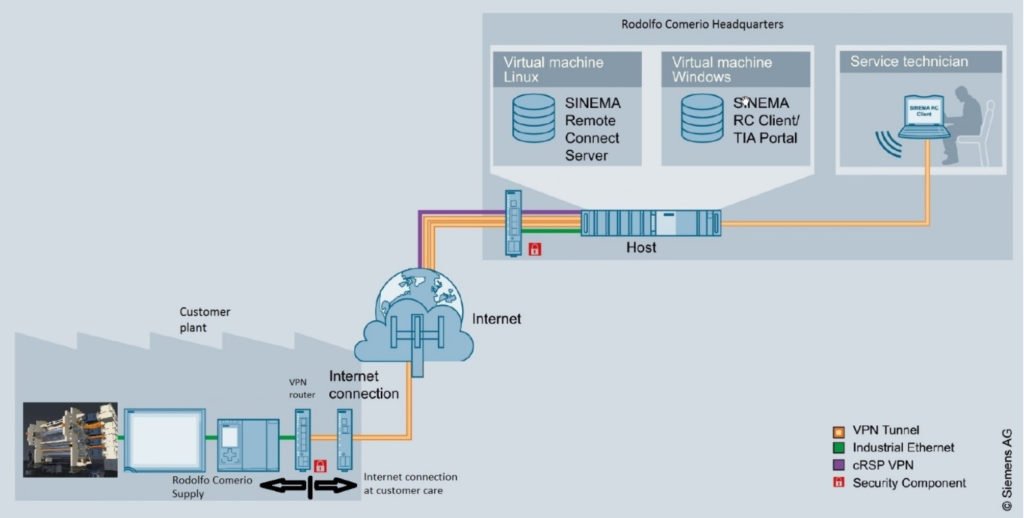

RODOLFO COMERIO is also able to provide timely remote assistance for all its systems thanks to RC VPN CONNECTINGSystem: RODOLFO COMERIO installs a VPN router in its main electrical cabinet which can connect (at customer request) with RODOLFO COMERIO VPN server located at RODOLFO COMERIO headquarters.

This server runs the Remote Connect server, a widely well-known system for remote service with the most updated features for security and prevention of undesired access both on RODOLFO COMERIO side and Customer side.